Hot Service Inspection Ports

By matching the inspection port to your process temperature, you can protect the integrity of the system from failure due to the loss of the insulation core.

As with all inspection ports, we recommend that after installation, some type of insulation material is inserted inside the 'inspection chamber' as the final step. In the event that the insulation material is lost or discarded during the inspection process, the backside of the inspection port will be subjected to the heat being radiated off of the surface of the pipe or vessel. If the inspection port is not rated for that temperature, heat failure of the stopper is possible. Once stopper failure occurs, water and air can penetrate into the inspection chamber and form surface corrosion that can lead to expensive repair costs or worse, critical failure.

Our inspection ports were specifically designed to protect against port failure from just such an event.

By using one of the inspection ports shown below within the listed operating temperatures, if the insulation material is lost or discarded, the integrity of the system is protected. We recommend you view our 'Inspection Ports' page if you haven't already for more information about the advantages of using APF's inspection ports over the competition.

Please click one of the links below when working with other operating temperatures.

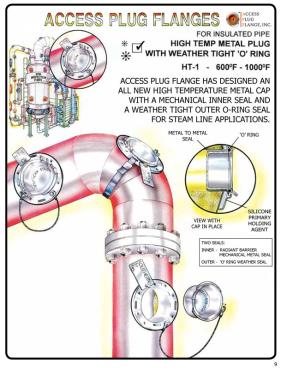

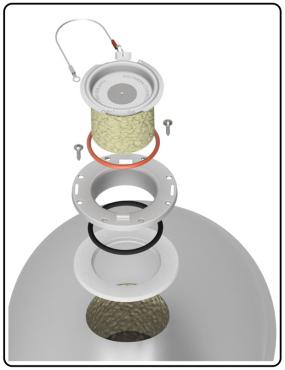

APF Inspection Port - HT1

- Designed for high-temperature applications but can be used at any temperature range above freezing where you want the security of an interlocking cup

- A hole saw is NOT required for installation, this prevents possible damage to the base metal from the hole saw pilot bit or accidental damage to hidden trace lines

- The inspector is shielded from the cut edge of the jacketing by the center draw of the flange, this allows you to comply with OSHA safety requirements

- Silicone applied under the flange is what provides the primary holding and sealing capabilities for the flange to the jacketing surface

- The elasticity of the large volume of silicone under the flange is what helps maintain the airtight and watertight seal during any thermal expansion or contraction of the jacketing material

- When installed per manufactures recommendation, a permanent airtight and watertight seal will be achieved

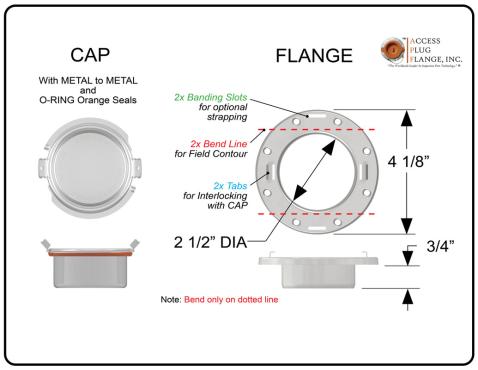

- 1/2" banding slots are provided in the flange to allow the inspection port to be banded in place when required

- Based on the application needed, all flat flanges can be field contoured to conform to a smaller radius

- Designed with an inner seal that is a metal to metal radiant barrier that helps prevent against heat loss thru the inspection port

- Outer seal is made by using a high-temperature o-ring for a weather-tight seal

- The deep draw of the metal cup is designed to provide efficient ambient cooling by dissipating any heat load to protect the outer o-ring seal

- Only Available in aluminum material and a 2 1/2" diameter

- Optional Separation Sleeve for material separation is available

| Part Number | Description | Working Hole Size for Inspectors | Minimum Temp Range | Max Temp Range | Flange Material | Stopper Material | |

| 2143001 | 2 1/2" Heat Check Assembly (HT-1), Aluminum Flat Flange, Deep Draw Aluminum Cup w/Copper Sleeve | 2 1/2" | 33°F | 1,000°F | Aluminum | Aluminum | |

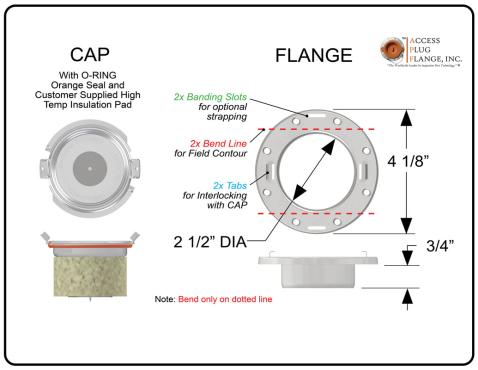

| 3153002 | 2 1/2" Heat Check Assembly (HT-2), Aluminum Flat Flange, Shallow Draw Aluminum Cup w/Copper Sleeve, Stainless Steel Pin & Washers | 2 1/2" | 33°F | 1,200°F | Aluminum | Aluminum | |

| 4163003 | 2 1/2" Aerogel Assembly (AG-1), Aluminum Flat Flange, Shallow Draw Aluminum Cup w/Copper Sleeve | 2 1/2" | 33°F | 1,000°F | Aluminum | Aluminum |

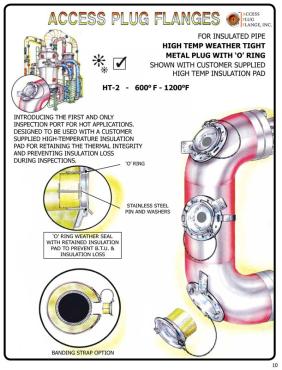

APF Inspection Port Assembly - HT2

- Designed for high-temperature applications but can be used at any temperature range above freezing where you want the security of an interlocking cup

- Designed to have a customer supplied insulation coupon attached to the center pin for a permanent solution against insulation loss during inspection

- A hole saw is NOT required for installation, this prevents possible damage to the base metal from the hole saw pilot bit or accidental damage to hidden trace lines

- The inspector is shielded from the cut edge of the jacketing by the center draw of the flange, this allows you to comply with OSHA safety requirements

- Silicone applied under the flange is what provides the primary holding and sealing capabilities for the flange to the jacketing surface

- The elasticity of the large volume of silicone under the flange is what helps maintain the airtight and watertight seal during any thermal expansion or contraction of the jacketing material

- When installed per manufactures recommendation, a permanent airtight and watertight seal will be achieved

- 1/2" banding slots are provided in the flange to allow the inspection port to be banded in place when required

- Based on the application needed, all flat flanges can be field contoured to conform to a smaller radius

- Outer seal is made using a high-temperature o-ring for a weather-tight seal

- The metal cup is designed to provide efficient ambient cooling to dissipate any absorbed heat to protect the inspector

- Only Available in aluminum material and a 2 1/2" diameter

- Optional Separation Sleeve for material separation is available

Explore Related Products

Our Thin Insulation Inspection Port also works well for the temperature range of 33°F to 1,000°F / 1°C – 648°C.

Have a Question?

* Denotes a required fieldSend us a message and our team of experts will get back to you shortly with a prompt response.